Grease Traps for Commercial Kitchens: What you Need to Know

Fats, oils and grease (FOG) are the inevitable byproducts of the cooking process. Commercial kitchen owners recognise the importance of managing what goes down the drain, but what’s the most comprehensive and cost-effective way to ensure that you don’t contribute to the greasy problems mounting up in the local sewage system?

In your search for effective FOG management technologies, you’ve inevitably come across grease traps. In this eBook, we cover the essentials to help you understand exactly what a grease trap does, how effective it is, and whether there are alternative or complementary solutions that can make things easier, safer, and more efficient for your restaurant, staff, and customers.

What is a Grease Trap?

Grease traps have been in use since the late 19th century and remain a common choice for establishments with commercial kitchens. Acting as a filtration system, the grease trap captures fats, oils, greases, and starches in wastewater before they enter the sewer system, where they can cause damage and harm.

A grease trap is a device that can be made of several different materials, including stainless steel, galvanised steel, and fibreglass. Installed under the sink, in the kitchen floor, or as a freestanding unit, grease traps aren't particularly inconspicuous –– especially when it comes to cleaning and maintaining them.

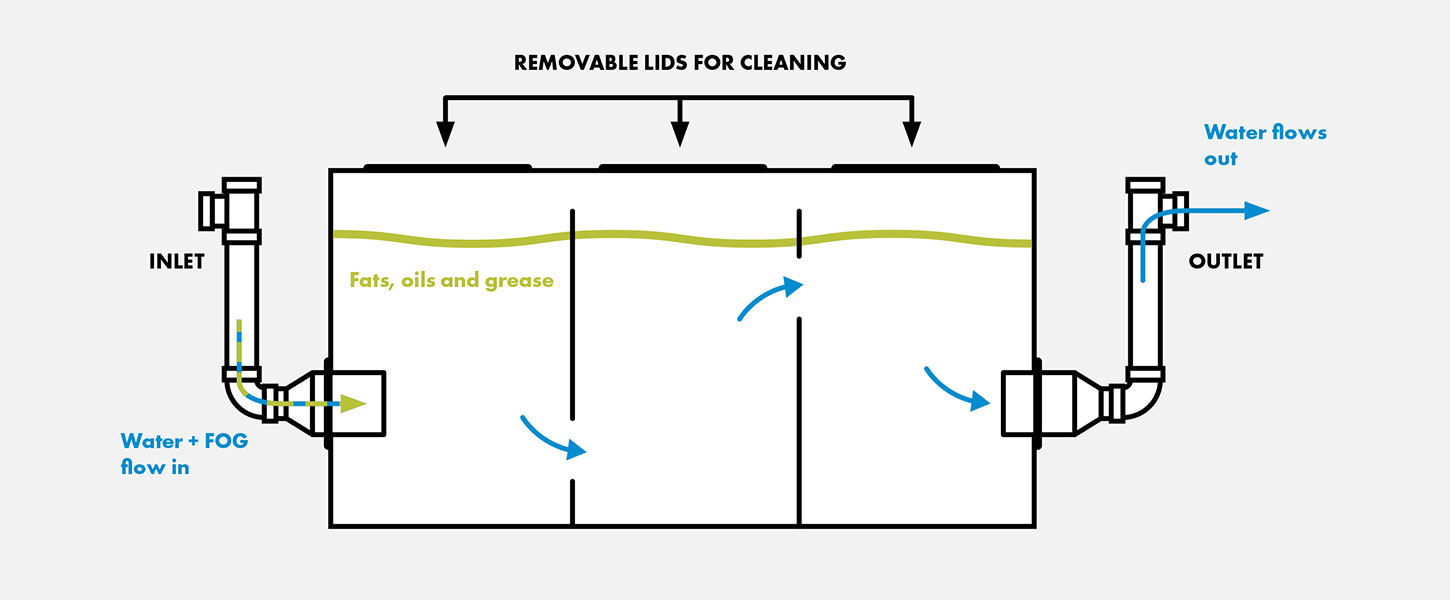

The grease capture system is comprised of an inlet and an outlet pipe. The grease trap itself sits inside the pipes between the sink (if installed there) and a discharge pipe that leads to a drainage system outside. Once grease accumulates inside the grease trap, it undergoes natural separation processes that remove water from grease.

How do Grease Traps Work?

Grease traps are designed to separate solids from liquids by slowing down the flow of water and allowing oils and fats to float to the top, while solids remain at the bottom, and the dirty water stays in the middle. At the end of the trap is a discharge pipe that leads out to your local sewer pipes system, where the filtered water, minus the FOG, is purged.

When a grease trap becomes full or clogged, you may experience problems such as slow drainage, odours, and flooding. To prevent this from occurring, grease traps should be emptied regularly by an experienced grease trap technician, who can also carry out routine checks to ensure your system is working as it should be and keep it free of pungent odours.

Do all Commercial Kitchens Need Grease Traps?

The simple answer is, it depends. In the UK, your local regulator will expect your establishment to manage its FOG and actively prevent them from entering the local sewage system. Installing a grease trap device, in particular, however, is not a legal requirement.

There are various laws that oblige commercial kitchens to manage their FOG effectively in order to protect communities, the environment and local infrastructure. In response to these requirements, some restaurants turn to grease traps as a solution.

Grease traps and UK law:

- The Building Regulations state that commercial food businesses that serve hot food and are connected to the mains drainage system should be fitted with an effective means of grease removal. (The Building Regulations 2010 Drainage and Waste Disposal (2015 Edition)

- Authorities may ask to see that your FOG waste is collected by a licenced contractor, requiring you to keep a thorough record of all collections. (The Environmental Protection Act 1990).

- The Environmental Protection Act also enables authorities to take legal action against your restaurant if waste-related smells affect your nearby environment – this is considered a statutory nuisance.

- If your commercial catering business is inspected and found to be the cause of damage to the local drainage system, Section 59 of the Building Act may allow authorities to charge you for the repair, renewal or cleansing of the system.

While there are no direct laws about grease trap installation, it’s clear that adequate and verifiable management of FOG needs to occur in order for your restaurant to stay compliant with regulations.

The FOG management solution you choose will depend on the size of your restaurant, the type of byproducts you create, and the commitment you are able to make to maintain your grease management system in order to keep up with guidelines and best practices.

Why do you Need to Prevent Grease from Entering the Water System?

The buildup of grease in the drains and sewage systems eventually becomes a problem that affects everyone. Uncontrolled FOG that make their way into your drains and the wider sewer system congeal to form damaging blockages that can cause flow restrictions and overflows, affecting homes and businesses alike. These problems become disruptive to your business, the environment and wider community.

From a business perspective, taking grease management seriously helps to keep your restaurant on the right side of the law and mitigates the risk of blocked drains, contamination and unpleasant smells. Nasty fines and a spoiled reputation are just some of the detriments your business may suffer if your restaurant is identified as the cause of a sewerage problem.

Installing an effective FOG management solution will not only keep your local authority happy, but will also help to reduce plumbing blockages, ensuring your kitchen keeps flowing freely!

What Limitations do Grease Traps Have?

In theory, standalone grease traps are a great solution. In practice, however, they’re not always the right solution for a commercial kitchen. Every kitchen should have a site assessment to determine the most appropriate method or equipment for controlling FOG. Here are just some of the factors you should bear in mind when considering a grease trap:

Commitment to regular maintenance is necessary

The grease you produce is an unavoidable and continuous byproduct of food preparation, requiring dedicated management. Like all grease management equipment, grease traps are not a set and forget solution. They require regular emptying and cleaning to remain free-flowing and functioning properly - this must be carried out by a licensed professional. It’s worth noting that bio-dosing can be used alongside a grease trap to prolong the service/cleaning intervals (see the next section!).

Fitting them into smaller spaces can be difficult

Standalone grease traps can be very bulky – with some built on the presumption that bigger is better. But this is not the case: size alone does not determine efficiency or effectiveness.

In many kitchens, especially in older buildings, layout and space is limited, which makes grease management and the installation of a conventional grease trap more of a challenge. In these situations, other (more compact) solutions can be a better option.

Cleaning and repairs can disrupt business

In a busy kitchen, there’s very little time to stop and manage a grease trap. The task can result in bad odours being emitted into your kitchen, and a very thorough clean-up job to ensure the kitchen is safe and hygienic afterwards. As a result, food preparation activities may have to come to a halt while an engineer handles any repairs or maintenance.

Grease Trap Alternatives

Grease traps vary in effectiveness depending on their design, how they are used, and how well they are maintained. For example, your kitchen team can do a lot to help the efficiency of your grease trap by paying more attention to what gets sent down the sink’s waste pipe.

When it comes to grease removal, conventional, standalone grease traps will get the job done, but they are not suited to every kitchen –– mainly due to space constraints, the frequency with which they must be emptied and the hygiene and odour issues associated with the process.

With all of this to consider, you may be wondering if there’s something better out there. While some alternative systems work very similarly to the traditional grease trap but offer the convenience of automation, other’s take an entirely different approach by metabolising FOG.

In your search for the best grease management solution, you’re likely to come across grease removal units and drain dosing systems. Each will offer specific benefits that you’ll have to weigh up according to your type of commercial kitchen operation and the long-term outcomes you hope to achieve.

Grease removal units

Grease removal units (GRUs) are a type of grease trap which collect FOG in a separate container to the main tank, for easy access and frequent emptying. There are two main types, mechanical GRUs (or automatic GRUs), which collect FOG automatically, and non-mechanical GRUs (or manual GRUs), which need operator intervention to do this. Both types require regular emptying, usually daily, and somewhere to store FOG while they await collection.

Biological drain dosing

A biological dosing system works to digest the FOG and starches (or FOGS) your kitchen produces before the wastewater leaves your premises. It delivers a timed, measured amount of bacterial solution directly into waste pipes, and can be used on its own or in conjunction with a grease trap. Historically, dosing systems were quite large and imposing, requiring a mixture of harsh chemicals and a fair amount of maintenance, but many of today’s are compact, eco-friendly and work automatically.

Biological dosing is not the same as enzyme dosing, which emulsify FOGS and can cause problems further down the line. Biological dosing will use live bacteria that metabolise FOGS particles; this is called bioremediation and is a safe and effective way of managing FOGS in commercial kitchen.

Mechline’s GreasePak solution uses naturally occurring, non-pathogenic microorganisms, specially chosen for their ability to degrade FOGS in low-oxygen conditions such as drains, where pH levels often fluctuate. Compact and wall-mounted, the GreasePak dispenser automatically delivers a daily dose of the highly-concentrated multi-strain solution, which contains over 500 million bacteria per gram, either directly into drains or into BioCeptor’s F.I.T (FOG, Intercept and Treatment) unit as part of our comprehensive BioCeptor FOGS management solution, where the bacteria forms into biofilms and breaks down captured FOGS.

As the FOGS are broken down into simpler compounds before they enter the drains, their impact on the sewage system and the environment is significantly minimised. Used in combination with other grease management systems, a drain dosing solution can noticeably diminish FOGS. However, it’s important to note that the contents of the bio-dosing solution will hugely determine its effectiveness.

Alternative grease management solutions are available to keep grease at bay without having to rely on grease traps, and they have the added benefit of improving your kitchen’s efficiency and reducing odours. But, if you already have a grease trap, you don’t necessarily need to uninstall it and start from scratch. Instead, you can implement combined measures for FOGS management to optimise your grease trap’s performance and prolong the intervals between emptying.

Need More Advice on Restaurant Grease Management?

To determine what equipment is right for your operation, start by evaluating onsite conditions–we can help you here. During this evaluation, it will be determined whether you need one or more applications to properly manage the discharge from your operation.

FOG are a common point of contention when it comes to commercial grease management. They can impact the sewage system with chemical imbalances and clog pipes with solids – all of which can have problematic outcomes for your restaurant. That’s why a high quality, purpose-built FOG management solution is an essential investment for any catering establishment.

We have the expertise to offer advice on what may be best for your restaurant business, as well as alternative and complementary solutions that can enhance the way you manage FOG. Whether you’re looking to optimise your grease trap or want a better approach to managing FOG in your commercial kitchen altogether, we’re here to help.

Book a 1:1 call with Mechline for expert FOG Management advice